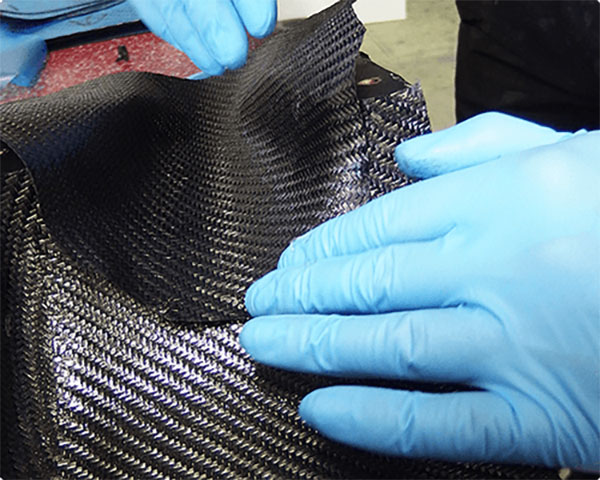

Re fana ka tlhahiso e hlophisitsoeng ea lihlahisoa tsa carbon fiber.Likarolo tsohle tsa carbon fiber le lihlahisoa li entsoe ka epoxy prepreg ea boleng bo holimo.Ka kakaretso re sebelisa autoclave le ontong ho phekola lihlahisoa tsa boleng bo holimo.

Carbon fiber (CF) ke mofuta o mocha oa fiber e nang le matla a holimo le modulus e phahameng, e nang le carbon e fetang 95%.E entsoe ka flake graphite microcrystalline le likhoele tse ling tsa manyolo tse kentsoeng ka lehlakoreng la axial la fiber, 'me thepa ea graphite ea microcrystalline e fumanoa ka carbonization le graphitization.Carbon fiber "e bonolo ka ntle 'me e thata ka hare".Boima ba eona bo bobebe ho feta ba aluminium, empa matla a eona a phahame ho feta a tšepe.E na le litšobotsi tsa ho hanyetsa kutu le modulus e phahameng.Ke thepa ea bohlokoa ho ts'ireletso ea naha, indasteri ea sesole le boenjiniere ba sechaba.Ha e na feela litšobotsi tse ka hare tsa carbon, empa hape e na le bonolo le ts'ebetso ea fiber ea textile, kahoo ke moloko o mocha oa fiber e matlafalitsoeng.

Mosebetsi oa likhoele tsa khabone ka har'a motsoako ke ofe?

Carbon fiber e na le thepa ea matla a phahameng, modulus e phahameng, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, ho khathala le ho hanyetsa ho phalla, motlakase oa motlakase le conductivity ea mocheso.E sebelisoa haholo-holo bakeng sa ho lokisetsa lisebelisoa tse kopantsoeng.

Sebaka sa Tšebeletso

■ Ho etsa hlobo

■ Phekolo ea masela esale pele

■ Pheko e entsoeng ka motsoako

■ mochini oa CNC

■ Kopano

■ Khalase ea ho qetela

Nyeoe ea Sehlahisoa

Theknoloji ea Tlhahiso

Pre-Preg ho autoclave

ho fana ka likarolo tsa boima ba 'mele tse bobebe tse fanang ka ponahalo e ntle haholo.Ho bopa ha carbon fiber pele ho pelehi ho na le ts'ebeliso ho mabelo a Formula One, har'a a mang.

Ho phekola ka ontong

Infusion ea resin

e nepahetse bakeng sa lintho tse kholo tsa moralo o rarahaneng o kenyelletsang litlhōrō tsa litafole, li-casings, likoahelo, lishiti.

Laminating ka letsoho

carbon fiber molding mokhoa o sebelisoang bakeng sa lihlahisoa tse nyenyane tse entsoeng ka mokhoa o bonolo moo ho boloka litšenyehelo ho le bohlokoa.

Lisebelisoa tsa Tlhahiso

Autoclave

Khatello e phahameng ea ts'ebetso ea 8 bar, mocheso o phahameng oa ho folisa 250 ° C - bakeng sa tlhahiso ea li-composites tsa boleng ba carbon fiber (pele ho pelehi).

Autoclave #1: 3 x 6m.

Autoclave #2: 0.6 x 8m.

Autoclave #3: 3.6 x 8m ho tla.

Setofo

Ovine - 4x2x2m, mocheso o phahameng: 220 ° C.

Mochine oa khatiso oa Hydraulic

Litekanyo tsa lipoleiti tse futhumatsang: 2000 x 3000 mm, khatello ea lithane tse 100.

Setsi sa machining sa CNC (3-axis)

Sebaka sa ts'ebetso: X: 3000 mm, Y: 1530 mm, Z: 300mm.

Sander e nang le lebanta le sephara

Bakeng sa lipampiri tsa sanding ho botenya bo lakatsehang, ho nepahala ha 0,05 mm.

Sehatsetsi Storage

E ka ba 30 ㎡ moo pre-pregs e bolokiloeng teng.

Kamore e hloekileng

Kamore ea rona e hloekileng e fana ka tikoloho e se nang tšilafalo ho beha lisebelisoa tse kopaneng, tse loketseng ho lamination ea pre-peg.

1000 sq meter

1000 square meter ea sebaka sa tlhahiso.

5000 square meter e ncha ea tla haufinyane.

Mochini oa X-Ray oa Digital

Bakeng sa ho hlahloba boleng ba litšoantšo tsa X-ray tsa lihlahisoa

Ke hobane'ng ha Weadell?

■ Re na le lisebelisoa tse tsoetseng pele tsa tlhahiso ea litlhaloso tse fapaneng.

■ Re kenya tšebetsong mekhoa e tsoetseng pele ea tlhahiso ho fihlela litlhoko le litlhoko tsa bareki.

■ Re sebelisa mekhoa e metle ka ho fetisisa e netefatsang lihlahisoa tsa boleng bo phahameng hammoho le moralo oa morao-rao.

■ Re fana ka lits'ebeletso le lihlahisoa tsa boleng bo holimo ka lebaka la boitseanape ba rona, litsebi tse nang le boiphihlelo bo holimo, lisebelisoa tsa sejoale-joale le khothatso e matla ea ho lula re fana ka khotsofalo e ikhethang ea bareki.

Phethahatso ea Morero

1. Therisano

2. Ho etsa moralo

3. Hlobo le mohlala

4. Mohlala

5. Tlhahiso ea Batch

6. Mechine

7. Kopano

8. Ho qeta

9. Taolo ea Boleng

10. Hlalosa